Conventional CNC turning

We use Czech CNC machines for turning.

We offer complex turning work.

Machinery

| number | working dimensions | machine type | application |

|---|---|---|---|

| 4 x | Ø 270 x 535 mm | S50 (TC-615) | small series production |

| 1 x | Ø 280 x 565 mm | SP 280 MC | small series production |

| 1 x | Ø 280 x 565 mm | SP 280 | small series production |

| 1 x | Ø 465 x 1000 mm | S80 CNC | small series production |

| 5 x | Ø 215 x 1000 mm | SV 18 | piece production |

| 1 x | Ø 500 x 2000 mm | SN 50 SA / 2000 | piece production |

Conventional CNC milling

CNC milling on vertical milling machines and 5D milling. We use modern control systems.

Strojní vybavení

| number | working dimensions | machine type | application |

|---|---|---|---|

| 1 x | Ø turntable plate 520 mm | MCV 1000D 5AX | small series production |

| 5 x | X / Y / Z – 754 x 500 x 550 mm | MCV 754 Quick | small series production |

| 1 x | X / Y / Z – 2030 x 810 x 810 mm | MCFV 2080 | small series production |

| 1 x | X / Y / Z – 750 x 500 x 500 mm | MCV 750 | small series production |

| 2 x | X / Y / Z – 1000 x 610 x 630 mm | MCFV 1060 LR | small series production |

| 1 x | X / Y / Z – 600 x 400 x 400 mm | FNG 40 CNC | small series production |

| 1 x | X / Y / Z – 600 x 400 x 400 mm | FNGJ 40 A | piece production |

| 1x | X / Y / Z – 490 x 340 x 190 mm | FN 25 | piece production |

| 1 x | X / Y / Z – 600 x 400 x 400 mm | FNGJ 32 | piece production |

| 1 x | X / Y / Z – 800 x 275 x 350 mm | FA 3 U | piece production |

Round and flat grinding

Machinery

| number | working dimensions | machine type | application |

|---|---|---|---|

| 1 x | Ø 250 x 630 mm | CNC BUA 25 | small series production |

| 1 x | Ø 250 x 630 mm | BHS 25 - 630 CNC | small series production |

| 1 x | Ø 250 x 1000 mm | BUA 25 - 1000 | piece production |

| 1 x | Ø 200 x 450 mm | BUA 20/450 | piece production |

| 1 x | Ø 250 x 1000 mm | ROBBI 1000R | piece production |

| 1 x | X / Y / Z – 1000 x 500 x 200 | BRH 50/III FPR | piece production |

| 1 x | X / Y / Z – 630 x 200 x 200 | BHR 200 AQ | piece production |

| 1 x | X / Y / Z – 630 x 200 x 200 | BRH 20.03 F | piece production |

Wire cutting

Machinery

| number | working dimensions | machine type | application |

|---|---|---|---|

| 1 x | X / Y / Z – 500 x 350 x 426 mm | AC progress V3 | piece production |

| 1 x | X / Y / Z – 550 x 350 x 256 mm | CUT 3000 S | piece production |

Sawing machine

dimensions: 290 x 290 mm

machine type:

Pegas-Gonda CNC

Kaltenbach

TM Jesenice

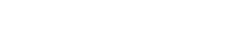

Laser

material for labeling: metal, plastic

machine type: Laserfibre LFQ20T - table laser marking machine with fiber laser

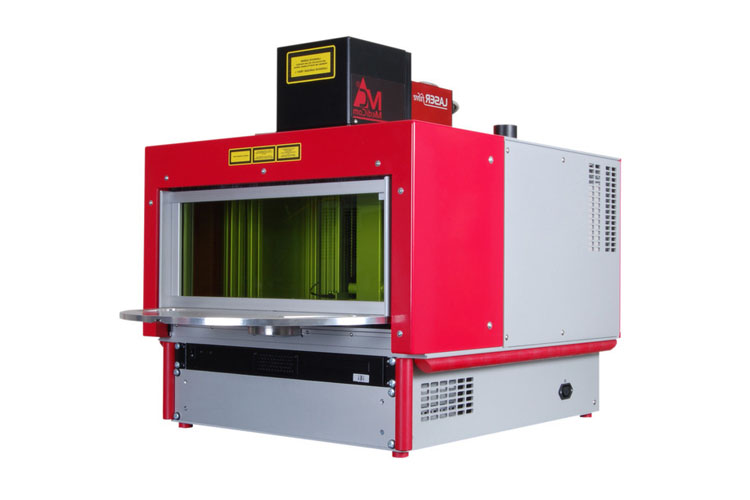

Used software CAD/CAM

BricsCAD

SolidCAM

SolidWorks

programming station HEIDENHAIN

Checking

3D coordinate measuring machine Pioneer Dea 1000 x 700 x 500

profilometer Mitutoyo CV 500

roughness measuring instrument Mahr

digital 2D altimeter LH-600 Mitutoyo

digital 2D altimeter HC1 Garant

analog microscopes

Conventional measuring instruments such as slide calipers, depth gauges, micrometers, passameters, hole gauges, protractors and gauges are used for routine measurements in production.

Own hardening plant

Heat treatment requires a longer time. We are able to provide hardening of smaller parts under time pressure.

Cooperation

We provide heat treatment, e.g. carburizing, hardening, nitriding, etc.

We can also provide surface treatment, especially zinc plating, blackening, hard anodizing, natural anodizing, chrome plating, nickel plating, rubberizing, etc. according to the customer's requirements.